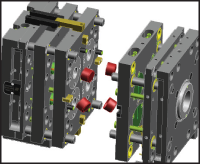

Standard Tooling and Engineering

|

To ensure consistent and good quality production AST Technology GmbH can assist customers with developing a company-specific tool standard or tool standard specification. This will allow OEM´s and moulders to feed tools into production with confidence, whether the tool is run in-house or transferred to another facility. Specifying mould components that are globally available for the tool build, maintenance and repair will reduce both lead times and downtime during production. Tool Standard Benefits:

|

Develop custom, company-specific |

AST Service Overview

Tool Design Review and Engineering - includes a thorough, structured review of existing tool design to ensure the best possible tool setup before the mould maker starts production. Support is provided by developing custom de-moulding/mould concepts to suit a specific application. Feedback is provided via an “AST Tool Design Review Report” and/or modified 3D CAD geometry.

Tool Requirement Specification (TRS) Review and Development - involves a complete evaluation of the customer’s production environment and range of componentry to verify where custom tooling applications are required. An audit of existing design guidelines and tool requirement specifications is performed, or new documents created.

Tool Standard Development and Maintenance -

-

Categorize range of customer components

-

Modular mould base development

-

Standardisation of tool construction and manufacturing

-

Hot runner standardisation

-

Mould base and hot runner reuse

-

Documentation: manuals and design guides

-

Tailored training for OEM´s, moulders and mould builders

-

Revision control, maintenance, value- and re-engineering of customer owned tool standard

AST customers often use the “Tool Design Review” service in combination with DFM reviews and injection moulding process optimisation for analysing and resolving existing problems in production. This can either be performed remotely or on-site with “hands on” processes in the production environment.

For detailed information please contact AST via email at contact@ASTTech.com or via phone at one of our global offices: Germany: +49 (0) 5731 496 2340; United Kingdom: +44 (0) 2033 990999; or North America: +1 847 487 1000.