Design for manufacturing

|

Because component design has a direct impact on both tooling and DFM Benefits:

|

Service and value engineering |

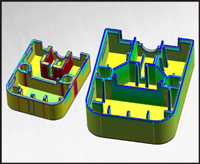

AST DFM Service Overview

DFM analysis on component structure and de-moulding includes:

-

Material selection and specification

-

Analysis on wall thickness, splitting, demoulding concept and tool structure

-

Value- / re-engineering to convert products from metal parts into injection moulded polymer components

-

Feedback on proposals in structured reports and/or within changed 3D CAD geometry

Flow analysis is offered for a wide range of applications:

-

Available for single shot, multi shot, insert moulding and gas assisted components

-

Analysis with focus on:

-

Filling profile and filling pressure

-

Shear rate and temperature

-

Cooling time, volumetric shrinkage and part deflection

-

Gate size and cycle time calculation

-

Mould functions such as venting and cooling feedback

-

-

Feedback in structured reports accom-panied by 3D animation files.

AST customers often use the DFM service in combination with tool design reviews and injection moulding process optimisation for analysing and resolving existing problems in production. This can either be performed remotely or on-site with “hands on” processes in the production environment.

For detailed information please contact AST via email at contact@ASTTech.com or via phone at one of our global offices: Germany: +49 (0) 5731 496 2340; United Kingdom: +44 (0) 2033 990999; or North America: +1 847 487 1000.