AST Customer Case Studies

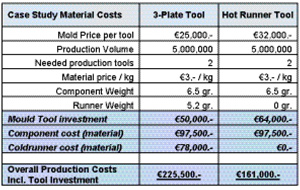

Tool Cost Versus Tool ProfitabilityWhen working with customers AST takes care to ensure that tool quality and performance will not be adversely affected by the mould buyer´s quest to control costs. Low tool prices can often lead to problems in production such as splitting, shut off, cooling & venting, by not taking care of simple tool design rules during the tool build. For example, by using 3-plate cold runners instead of hotrunner technology, further savings on tool costs can be achieved. However, they ultimately cost more due to the reduction of process control and performance and because they use up a lot of resin, which directly impacts piece part price. In addition, one must deal with the bad appearance of gate points on direct gated components. By introducing hotrunner technology to mass production moulds, especially for higher volume products, a savings of up to 80% on resin, plus better process control and performance, can be achieved depending on the component weight. Additionally, wear from the use of low quality steel and not using protective coatings will always lead to shorter tool life. |

|

|

|

|

|

|

|

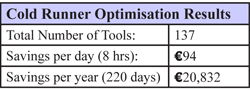

Cold Runner OptimisationCold runner gating systems remain a common gating solution, with 3-plate cold runner systems often used in mass production tools. So obtaining the right cold runner design and dimension is critical for optimum material usage and component quality. AST recently developed a tool for its exclusive CAD system to support internal DFM work. This tool will allow mould designers to deliver a complete and optimised 3D geometry of a cold runner system for tooling to the customer. Combined with share rate and gate size calculation, it will ensure the best, most efficient cold runner design for production. To illustrate, AST recently applied this new tool and worked through calculations for 137 production tools using 2-plate and 3-plate cold runner systems being run by an OEM customer. In addition to optimising the part performance and heat release to the tool, AST helped this customer realise an average savings on material usage of 15% on all 137 tools.

|

Customer gained a 15% savings by simply

Click HERE to download a printable PDF.

|

|

|

|